Leaders and Tippet

Definitions

It all starts with knots. Everyone learns the surgeon’s knot to join monofilament together, but don’t understand why. Why add monofilament pieces to a leader, or why change the monofilament size at the end of the leader? There are good reasons, but let’s start with some basic statements and definitions. The leader is defined as a tapered piece of monofilament connecting the fly line and the fly. Tapering means it’s thick at one end, thin at the other. Tippet (for our purpose) is the thinnest part of the leader, where we tie the fly on. Tippet is sized by diameter, not pound test, which is expressed as an X value. The smaller the X value, the thicker the tippet, so 5x tippet is thinner than 2X tippet. This sizing system dates to the time when leaders were made of gut (pre-1950 or so). Gut pieces came in very few diameters. To make your piece of gut thinner, you pulled it through a V shaped razor. One pull through the razor- the gut piece is now thinner- 1X. Two pulls through the razor- gut is now even thinner- 2X. That’s how we got the X nomenclature. All leaders are designated by length and tippet, so a 9′ 4X leader is nine foot in length, tapering down to 4X diameter.

Matching Diameter To Fly Size

Flies are also sized in the same counter-intuitive way. The larger the numeric value of a fly, the smaller the size of the fly, meaning a size 12 fly is smaller than a size 8 fly. This system is based on wire gage used to build the hook. The thinner the wire, the larger the number. Knowledge of fly size and X diameter is important for matching the proper tippet size to your fly. There are 2 rules for sizing tippet to fly, the Rule of 3 and the Rule of 4. Take your fly size (Example: size 12) and divide it by 3. You get 4. Or, take your fly size and divide it by 4. You get 3. So a size 12 fly would be properly matched with size 3X or 4X tippet. For a size 8 fly, divide by 4, to get 2. Divide by 3 and get 2.666, so we round up and get 3. So a size 8 fly would be properly matched with 2X or 3X tippet. Those two rules will provide the correct tippet size for your chosen fly.

Tapered Leaders

Tippet size is dependent on fly size, and we need to apply that knowledge effectively to our leader design. To understand leaders, we need to understand the energy transfer that goes through them. Energy transfer is most easily understood as water being poured into a gutter. If you place a gutter flat on the ground, and splash a bucket of water into it, the water travels a certain distance down the gutter, and then stops. The energy has dissipated. But if you were to take that gutter and taper it, compressing the path of the water, the water travels much further before it stops. In essence, this is what a leader does. The leader starts thick and tapers down to the tippet, allowing the energy from the cast (generated by the fly rod) to flow effectively through the leader. Point of fact- the front taper of the fly line does exactly the same thing, tapering the energy of the cast into the leader. So, a leader would look like this diagram, if seen from the side.

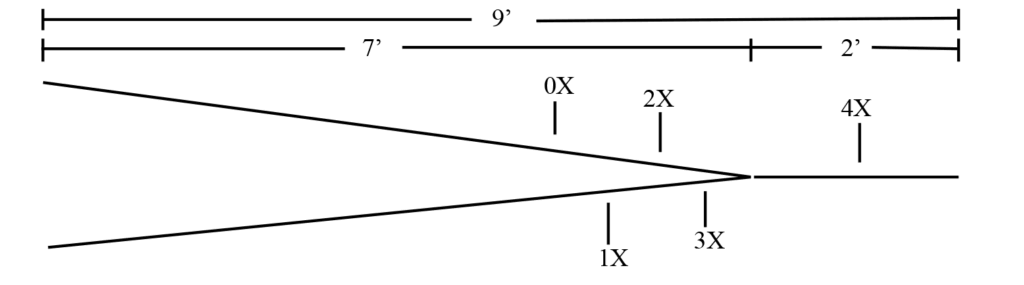

You can see the taper of this leader as it goes from the butt (thick end) down to the tippet (level skinny end). The example shown is a 9′ 4X leader. It is 9′ in total length, with 7 feet of tapered monofilament and 2′ of 4X level tippet at the end. Perfect for our size 12 fly. So you tie on your size 12 fly, and use up 4″ of tippet tying the clinch knot. And you lose that fly. So you tie on another size 12 fly, and again lose 4″ more of tippet to the knot. Then decide to change flies. Cut it off, tie on another size 12 fly – lose 4″ of tippet again. And so on. After 5-6 flies have been tied on, there is no more 4X tippet left on your leader. To replace the 4X tippet, use the Surgeon’s Knot to add another 2′ of 4X tippet. Adding tippet protects the integrity of the leader’s taper, which is why you paid $5.00 for 9’ of monofilament. Adding tippet protects that investment.

Splicing Tippet to Leader

Here’s where leaders get interesting. You want to change to a size 8 fly, which means your leader’s tippet should be 2X. Note on the leader diagram there are markings where the diameters of 3X, 2X, 1X and 0X are located. To add 2X tippet, cut the tapered section of the leader at the 2X point. Please note there are no markings on an actual leader, so you will need to judge the diameter by sight or feel (not as hard to do as it sounds). Then use the surgeon’s knot to add a piece of 2X tippet, a little over 2′ long. Then go through the fly-tying-on procedure again, now using the 2X section of tippet and size 8 flies. With this step, you have maintained the integrity of the taper of your leader, but have changed tippet sizes.

Now it gets more interesting. You want to return to using a size 12 fly. You will do this often, changing fly sizes, and by necessity, tippet sizes. What is the procedure? Look at the leader diagram. The approximate length of the leader between 2X and the start of the 4X is 6″. So, cut your 2X tippet off at about 10″. Then use the surgeon’s knot to attach a little more than 2′ of 4X tippet to your 10 inches of 2X monofilament. You will lose about 4″ from each piece (giving 6″ of 2X, and approximately 2′ of 4X), and now you have re-created a 4X tapered leader. Why do we do all this?

Simple. Economics and efficiency. It costs a lot of money if you pull out a brand new leader every time you’ve tied on 5 flies. It’s also annoying to change leaders every time you change fly size. So we use our knowledge of tapers, as shown by the water in the gutter, to maintain efficient energy transfer through our leader. Efficient energy transfer becomes more complicated when adjusting your leader from 0X to 5X. In order to maintain proper energy transfer, you need to step down (jargon for making your leader thinner) using 2 pieces of monofilament, not one as in the previous example. There are two rules for maintaining proper leader taper. Never jump more than 2 sizes of tippet at a time (so no tying the 5X directly to the 0X). You should go from 0X to 2X, then 2X to 4X, then tie on the 2′ piece of 5X tippet to complete your 5X leader. Second rule, when tapering your leader, the subsequent piece tied on (the skinnier piece) should never be longer than the piece tied on previously, until you get to the tippet. So if the 2X piece is 8″ long, then the 4X piece must be less than 8″ long. This protects the efficiency of our leader’s taper. Again, go back to your leader diagram. Check the approximate distance between the 0X point and the 4X point, and then make sure your 2 pieces of step down leader are approximately the same length.

Why do we create leaders this way? Let’s start with reasons for not tying 5X tippet directly to 0X, by going back to the water in the gutter. If you abruptly change from wide gutter to narrow gutter, most of the water will spill over the sides, and very little water will enter the narrow section of gutter. Additionally, water entering the narrow part has little power behind it. The same principle applies to energy transferring from a thick piece of tippet (0X) to thin tippet (5X).

The reason the subsequent piece of leader is always shorter than the previous piece is explained this way. During casting, as your leader extends, it loses energy (thin can’t carry as much energy as thick). So a shorter subsequent piece of thinner mono always makes sure the energy being transferred is sufficient to continue the turnover of the leader.

The tippet always breaks that last rule. Simply put, you want a little squiggle, or slack, at the end the leader. The long, thin piece of tippet transfers energy quite poorly, allowing the energy to dissipate and the leader to develop some squiggles. These squiggles create slack, allowing the fly to float naturally, unaffected by the current.

Importance of the Leader

The leader is one of the most important pieces of tackle we use, because for a fly to move naturally it must be drag free. Slack allows the fly to float freely. A tight (straight) leader is immediately affected by the different currents in the river, causing the fly to be pulled by the leader. This pulling movement causes the fly to move counter to the current, which is the definition of drag. A properly tapered leader transfers enough energy to be accurate, while allowing some slack to be present near the fly for proper drag free presentation.

Let’s return to matching the tippet size to the fly. Imagine a size 12 fly attached to a piece of 1⁄4″ diameter rope. The thick rope transfers energy very well, and easily extends straight out. However, the thick rope is greatly affected by the current due to its size, pulling the relatively small fly along the path of the rope. If the fly is following the path of the rope, it is not floating naturally with the current. It’s dragging, and that is a dramatization of what happens when using tippet that is too thick for the fly.

Imagine the same size 12 fly attached to fine sewing thread. With no effect from current on the thin, supple thread, the fly floats naturally, which is drag free floating. However, the thin thread is incapable of transferring enough energy to “turn over” the fly accurately. Turn over means the leader extending away from you, not curved back at you. That is the dramatization of using too thin a tippet. That’s the reason it’s so important to match tippet size to fly. The tippet must be thin enough to allow the fly to float freely, while being thick enough to transfer the energy to the fly.

There’s more to building tippets. Imagine taking a 2 foot piece of tippet and holding it in your left hand, with two inches extending to the right. With your right hand, pull the 2 inches of tippet hard and to the right, and let go. The 2 inch piece of tippet is stiff and remains parallel to the floor. Now imagine holding the leader in your left hand with 23 inches extending to the right. With the right hand, pull the 23″ of leader hard and to the right and let go. The leader flops down. What does that tell us? If you only have a couple of inches of tippet on your leader, even if it is correctly matched to the size of the fly, it will be stiffer than if you had a couple of feet of tippet. The shorter piece of tippet may affect the float of the fly, while the longer piece is less likely to affect the fly’s drift. So, if a longer piece of tippet is better, why not tie on 25′ of 5X tippet and never tie another surgeon’s knot again? Because the energy generated by the cast will not transfer along such a long length of very thin conduit (tippet), and you won’t be able to cast it.

Some additional points about leaders. The longer a tippet you can control, and stress control, the better your fly will float. The thinner a tippet you can control, the better your fly will float. The longer a leader you can control, the better your fly will float. Leader tapering is trying to get a long, thin tippet to turn over accurately, and provide a drag free drift. The leader is not just an invisible link between the fly and the fly line, it is what controls the fly on the water, and that is why it is so important.

And while these concepts are described in terms mostly affiliated with dry flies, the same leader design concepts hold true for nymph fishing. Thinner and longer gives a better drift. And with nymphing, thinner is also better because thin tippet is less affected by sub-surface currents than thicker tippet, and sinks more rapidly. The only time these tippet concepts are not important is when fishing a streamer style fly. Because a streamer is fished on a tight line, there is no need for drift, and therefore, less need for many of these other techniques. But when nymphing or fishing dries, the ability to balance and control your leader to provide a drag free drift is paramount.

Before the advent of extruded tapered leaders, as we have today, a leader was created by knotting together many pieces of monofilament of various lengths and diameters. Almost every book on fly fishing up until about 1975 had a formula for creating the perfect hand tied leaders. Many older anglers learned how to create leaders this way, and while there are disadvantages, there were some advantages as well.

You learned your knots, because each leader required tying anywhere from 7-11 pieces of mono together, and in specific lengths. You also rapidly learned how leaders worked, because you had to build them. Changing designs was simplified, because adjustments were actually made easier by the fact that each diameter was clearly labeled, with a knot at each end. Cause and effect was easily seen, because changing section length was so simple. It allowed anglers to understand, on a fundamental level, how a leader worked, and how to adjust it to make it more effective. Anglers learned they could make a leader behave in any way by adjusting its length and taper. To turn a leader over in a heavy wind, use a short, rapid taper. Or create a leader that allows your fly to land gently by extending the taper and using thinner diameters. It’s interesting to go back and study those old leader taper diagrams, to see what a taper looks like and learn about the actual leader diameters used throughout the taper. The continuously tapered leader does the same job as the hand tied leader, so it would make sense that the relative lengths of the different diameters would be the same. Armed with your taper knowledge, and the ability to balance tippet size to fly size, the leader will go from being something you tie on to something that will actually help you catch fish.